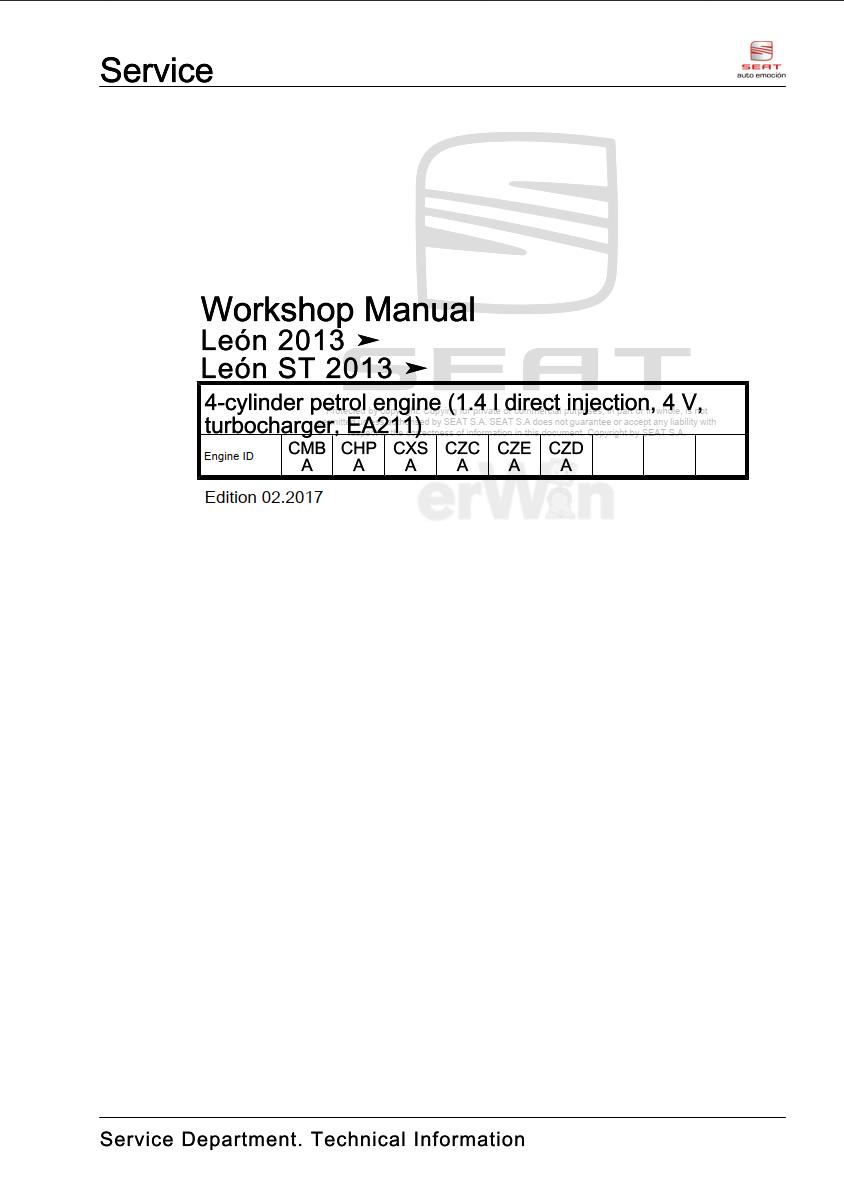

Leon 2013- Leon ST 2013-. Edition 02.2017. Engine ID: CMBA, CHPA, CXSA, CZCA, CZEA, CZDA. Technical information should always be available to the foremen and mechanics, because their careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a matter of course, be observed.

List of Workshop Manual Repair Groups

Repair Group

00 – Technical data

10 – Removing and installing engine

13 – Crankshaft group

15 – Cylinder head, valve gear

17 – Lubrication

19 – Cooling

21 – Turbocharging/supercharging

24 – Mixture preparation – injection

26 – Exhaust system

28 – Ignition system

CONTENTS

- 00 – Technical data

- 1 Identification

- 1.1 Engine identification number/engine data

- 2 Safety instructions

- 2.1 Safety precautions when working on fuel supply system

- 2.2 Safety precautions for working on vehicles with start/stop system

- 2.3 Safety precautions during road tests in which testing and measuring equipment is used

- 2.4 Safety precautions when working on the cooling system

- 2.5 Safety precautions when working on ignition system

- 3 Repair instructions

- 3.1 Rules for cleanliness

- 3.2 General notes

- 3.3 General repair instructions

- 3.4 Vacuum system: checking

- 3.5 Foreign particles in engine

- 3.6 Contact corrosion

- 3.7 Routing and attaching pipes and wiring

- 1 Removing and positioning the engine

- 1.1 Engine: dismounting

- 1.2 Separating engine and gearbox

- 1.3 Securing engine to engine and gearbox support

- 1.4 Engine: fitting

- 2 Assembly mountings

- 2.1 Exploded view – assembly mountings

- 2.2 Supporting engine in installation position

- 2.3 Removing and installing engine mountings

- 2.4 Removing and installing gearbox mounting

- 2.5 Removing and installing pendulum support

- 2.6 Checking adjustment of assembly mountings

- 2.7 Adjusting assembly mounting

- 1 Identification

- 13 – Crankshaft group

- 1 Cylinder block (pulley end)

- 1.1 Exploded view – poly V-belt drive

- 1.2 Removing and installing poly V-belts

- 1.3 Assembly overview – Sealing flange, belt pulley end

- 1.4 Removing and installing tensioner for poly V-belt

- 1.5 Removing and installing vibration damper

- 1.6 Removing and installing engine support

- 1.7 Crankshaft oil seal- pulley side: replace

- 1.8 Removing and installing sealing flange (pulley end)

- 2 Cylinder block, gearbox end

- 2.1 Exploded view – cylinder block, gearbox end

- 2.2 Removing and installing flywheel

- 2.3 Removing and installing sealing flange (gearbox end)

- 3 Crankshaft

- 3.1 Crankshaft dimensions

- 3.2 Renewing needle bearing in crankshaft

- 3.3 Measuring crankshaft axial clearance

- 4 Pistons and conrods

- 4.1 Assembly overview – pistons and conrods

- 4.2 Removing and installing pistons

- 4.3 Removing and installing oil spray jet

- 4.4 Checking pistons and cylinder bores

- 4.5 Checking radial clearance of conrod bearings

- 1 Cylinder block (pulley end)

- 15 – Cylinder head, valve gear

- 1 Cylinder head

- 1.1 Exploded view – cylinder head

- 1.2 Exploded view – camshaft housing

- 1.3 Removing and installing cylinder head

- 1.4 Removing and installing camshaft housing

- 1.5 Test compression pressure

- 2 Toothed belt drive

- 2.1 Exploded view – toothed belt cover

- 2.2 Exploded view – toothed belt

- 2.3 Checking distribution timing

- 2.4 Detaching toothed belt from camshaft

- 2.5 Timing belt: removing, fitting, tensioning

- 3 Valve control

- 3.1 Assembly overview – valve gear

- 3.2 Valve 1 for variable distribution N205 removing and fitting

- 3.3 Removing and installing exhaust camshaft control valve 1 N318

- 3.4 Removing and installing cam actuators

- 3.5 Removing and installing camshaft adjuster

- 3.6 Measuring axial play of camshaft

- 3.7 Removing and installing camshaft oil seal

- 3.8 Removing and installing valve stem seals

- 4 Inlet and exhaust valves

- 4.1 Checking valve guides

- 4.2 Valves: checking

- 4.3 Valve dimensions

- 1 Cylinder head

- 17 – Lubrication

- 1 Sump, oil pump

- 1.1 Exploded view – sump/oil pump

- 1.2 Removing and installing oil level and oil temperature sender G266

- 1.3 Removing and installing sump (bottom section)

- 1.4 Oil pump: removing and installing

- 1.5 Removing and installing sump (top section)

- 1.6 Engine oil

- 2 Engine oil radiator

- 2.1 Assembly overview – engine oil cooler

- 2.2 Removing and installing engine oil cooler

- 3 Crankcase breather system

- 3.1 Exploded view – crankcase

- 3.2 Removing and installing the oil separator

- 4 Oil filter/oil pressure switches

- 4.1 Exploded view – oil filter housing/oil pressure switches

- 4.2 Removing and installing oil pressure switch F1

- 4.3 Removing and installing oil pressure switch for reduced oil pressure F378 . . . .

- 4.4 Removing and installing valve for oil pressure control N428

- 4.5 Checking oil pressure

- 1 Sump, oil pump

- 19 – Cooling

- 1 Cooling system/coolant

- 1.1 Connection diagram – coolant hoses

- 1.2 Draining and filling coolant

- 1.3 Check the cooling system for leaks

- 2 Coolant pump/thermostat assembly

- 2.1 Exploded view – coolant pump and thermostat

- 2.2 Exploded view – electric coolant pump

- 2.3 Exploded view – coolant temperature sensors

- 2.4 Removing and installing coolant pump

- 2.5 Removing and installing toothed belt pulley for coolant pump

- 2.6 Cooling system thermostat: removing and installing

- 2.7 Removing and installing electric coolant pump

- 2.8 Removing and installing coolant temperature sender G62

- 2.9 Removing and installing coolant temperature sender at radiator outlet G83

- 3 Coolant pipes

- 3.1 Exploded view – coolant pipes

- 3.2 Removing and installing coolant pipes

- 4 Radiator/radiator fans

- 4.1 Exploded view – radiator/radiator fans

- 4.2 Exploded view – radiator cowl and radiator fans

- 4.3 Removing and installing radiator

- 4.4 Removing and installing cooler for charge air cooling circuit

- 4.5 Removing and installing radiator cowl

- 4.6 Removing and installing radiator fans

- 1 Cooling system/coolant

- 21 – Turbocharging/supercharging

- 1 Turbocharger

- 1.1 Exploded view – turbocharger

- 1.2 Turbo compressor: removing and fitting

- 1.3 Removing and installing charge pressure positioner V465

- 2 Supercharger air system:

- 2.1 Assembly overview – charge air system

- 2.2 Removing and installing charge air pressure sender GX26

- 2.3 Removing and installing charge air cooler

- 2.4 Checking charge air system for leaks

- 1 Turbocharger

- 24 – Mixture preparation – injection

- 1 Injection system

- 1.1 Overview

- 1.2 Reducing fuel pressure in high-pressure section

- 2.1 Assembly overview – fuel rail with injectors

- 2.2 Removing and installing fuel rail

- 2.3 Removing and installing injectors

- 2.4 Cleaning injectors

- 3 Air filter

- 3.1 Exploded view – air cleaner housing

- 3.2 Removing and installing air filter housing

- 4 Intake manifold

- 4.1 Intake manifold – exploded view

- 4.2 Removing and installing intake manifold

- 4.3 Removing and installing throttle valve module GX3

- 4.4 Cleaning throttle valve module GX3

- 5 Sensors

- 5.1 Remove and install intake manifold sender GX9

- 5.2 Removing and installing fuel pressure sensor G247

- 5.3 Checking fuel pressure sender G247

- 6 Engine control unit

- 6.1 Removing and installing engine control unit J623

- 7 High-pressure pump

- 7.1 Exploded view – high-pressure pump

- 7.2 Removing and installing high-pressure pump

- 7.3 Removing and installing high-pressure pipe

- 8 Lambda probe

- 8.1 Exploded view – Lambda probe

- 8.2 Removing and installing lambda probe 1 before catalytic converter GX10 / lambda probe 1 after catalytic converter GX7

- 1 Injection system

- 26 – Exhaust system

- 1 Exhaust pipes/silencers

- 1.1 Exploded view – silencers

- 1.2 Removing and installing silencers

- 1.3 Disconnecting exhaust pipes/silencers

- 1.4 Align exhaust system to be free of stress

- 1.5 Checking exhaust system for leaks:

- 2 Emission control

- 2.1 Assembly overview – emission control

- 2.2 Removing and installing catalytic converter

- 1 Exhaust pipes/silencers

- 28 – Ignition system

- 1 Ignition system

- 1.1 Assembly overview – ignition system

- 1.2 Spark plug test data

- 1.3 Removing and installing ignition coils with output stages

- 1.4 Removing and installing knock sensor

- 1.5 Removing and installing Hall sender

- 1.6 Removing and installing engine speed sensor G28

- 1 Ignition system

Language: English

Format: PDF

Pages: 373

Seat 4-cylinder petrol engine 1.4L direct injection, 4 V, turbocharger, EA211