Save Hundreds on Repairs—Learn Pro Techniques to Fix Leaks, Restore Performance, and Avoid Costly Replacements!

1. Why Exhaust Manifolds Crack ⚠️

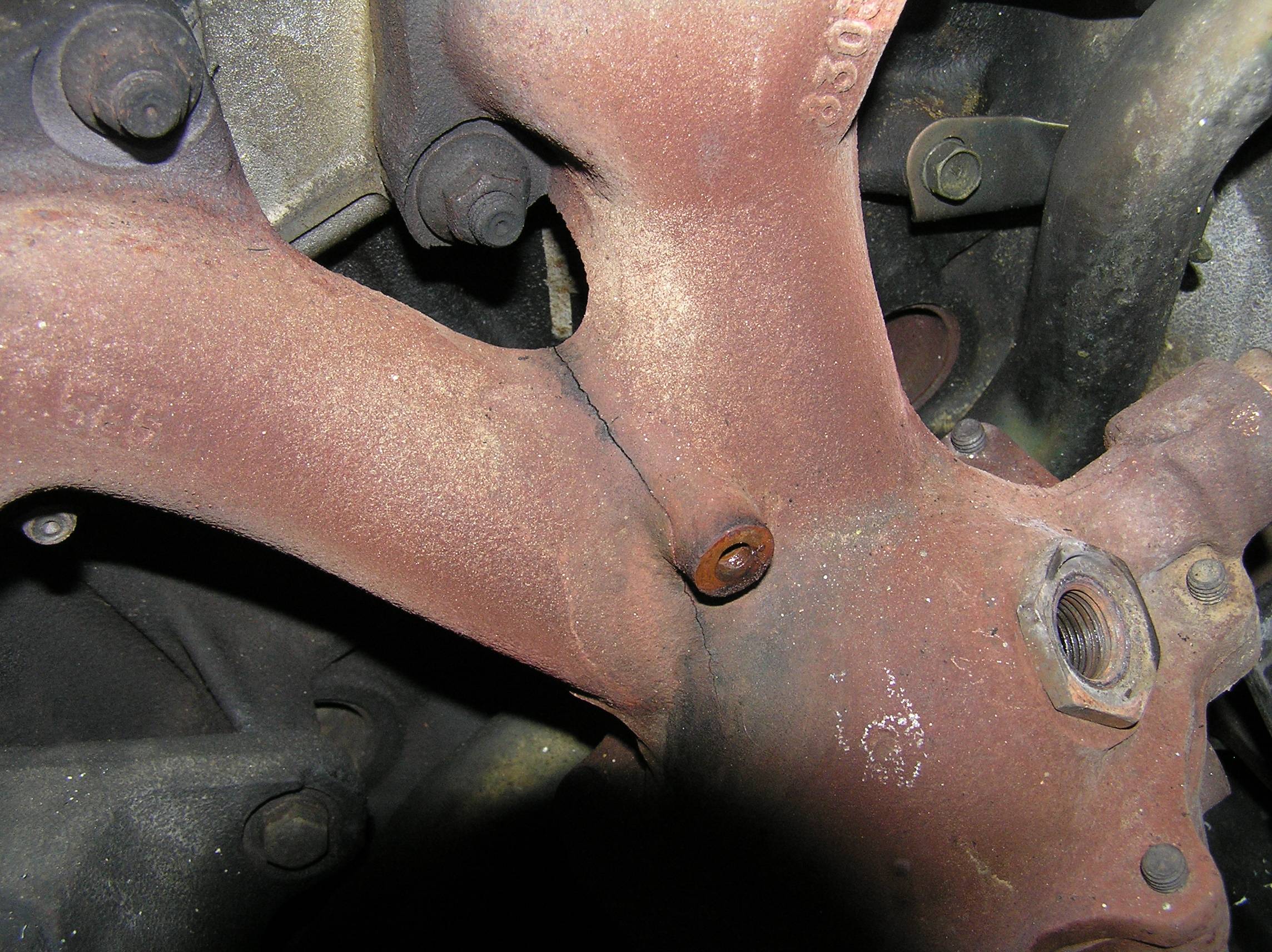

Exhaust manifolds endure extreme heat (up to 1,600°F), vibration, and thermal cycling, leading to stress fractures over time. Common causes include:

- Thermal fatigue: Repeated heating/cooling cycles weaken metal.

- Corrosion: Road salt and moisture accelerate rust.

- Poor welds: Factory or aftermarket defects.

- Engine mods: Turbocharging strains stock manifolds.

Key Stat: A cracked manifold can reduce engine efficiency by 10–15% and trigger check engine lights (P0420/P0430).

2. Tools & Materials You’ll Need 🧰

| Tool | Purpose | Cost |

|---|---|---|

| MIG/TIG Welder | For steel manifolds (140+ amps) | 300–1,500 |

| Arc Welder | Best for cast iron (nickel rods) | 100–300 |

| Angle Grinder | Clean cracks and prep surfaces | 50–150 |

| Wire Brush/Sandblaster | Remove rust and carbon buildup | 20–200 |

| High-Temp Paint | Protect post-weld | 10–20 |

| Infrared Thermometer | Monitor preheat/cool-down temps | 30–80 |

| Clamps/Vise | Hold manifold steady during welding | 20–100 |

Pro Tip: Use nickel-based rods (e.g., Ni-99) for cast iron; ER309L wire for stainless steel.

3. Step-by-Step Welding Guide 🔧

Step 1: Remove the Manifold

- Let the engine cool completely.

- Disconnect the oxygen sensor and unbolt the manifold from the engine block.

- Remove heat shields and supporting brackets.

Step 2: Clean the Manifold

- Degrease: Soak in parts cleaner or use brake cleaner.

- Grind: Use a carbide burr or angle grinder to remove rust, carbon, and paint around the crack.

- Sandblast: For thorough cleaning (optional).

Red Flag: Residual carbon can weaken welds—clean until bare metal shines!

Step 3: Inspect for Hidden Damage

- Dye Penetrant Test: Spray fluorescent dye to reveal hairline cracks.

- Tap Test: Lightly hammer the manifold—cracked areas sound dull.

Case Study: A Subaru owner found 3 hidden cracks after a dye test.

Step 4: Prep the Crack

- V-Groove the Crack: Grind a 60–70° groove along the fracture for weld penetration.

- Drill Stop Holes: At each end of the crack to prevent spreading (1/8” drill bit).

Pro Tip: Preheat cast iron to 400–500°F with a torch to avoid thermal shock.

Step 5: Weld the Manifold

- Cast Iron:

- Preheat to 500°F.

- Weld short 1–2” beads with Ni-99 rods (DC reverse polarity).

- Peen each bead with a ball-peen hammer to relieve stress.

- Steel/Stainless:

- MIG weld with ER309L wire (argon/CO₂ gas).

- Use stitch welds (skip 1” between beads) to minimize warping.

Step 6: Post-Weld Treatment

- Cool Slowly: Wrap cast iron in a fire blanket or bury in sand for 24 hours.

- Grind Smooth: Flush welds with the manifold surface.

- Pressure Test: Block one end, pressurize with soapy water, and check for bubbles.

Step 7: Reinstall & Protect

- Reattach the manifold with new gaskets and bolts (use anti-seize).

- Apply high-temp ceramic paint (1,200°F+ rated) to prevent rust.

4. Common Mistakes to Avoid 🚫

- Skipping Pre/Post-Heating: Cast iron cracks from rapid temp changes.

- Overheating Thin Areas: Warps the manifold, causing leaks.

- Ignoring Stop Holes: Cracks will spread beyond the weld.

- Using Wrong Filler: Standard rods won’t hold under thermal stress.

5. When to Replace Instead of Weld 🛑

- Multiple Cracks: More than 3 fractures signal systemic failure.

- Severe Corrosion: Metal thickness <1/8”.

- Aftermarket Upgrades: Stock manifolds often re-crack under boost—opt for headers.

Cost Comparison:

- DIY Weld: 50–200 (materials).

- New Manifold: 150–800 (OEM vs. performance).

- Pro Welding: 200–500.

6. Alternative Fixes (Temporary)

- Exhaust Tape/Epoxy: JB Weld Extreme Heat ($10) for small cracks (lasts 6–12 months).

- Bandage Clamp: Dorman HELP! Exhaust Repair Kit ($20).

Pro Tip: Temporary fixes buy time but aren’t substitutes for welding.

7. FAQs ❓

Q1: Can I weld a manifold without removing it?

A: Possible but risky—heat can damage sensors, wiring, and nearby components.

Q2: How long will the repair last?

A: Properly welded manifolds last 3–5+ years; epoxy lasts <1 year.

Q3: Can aluminum manifolds be welded?

A: Yes, with TIG and 4043 filler rod—but aluminum cracks more easily.

Q4: Why does my welded manifold still leak?

A: Missed a micro-crack, insufficient penetration, or warping during cooling.

Q5: Is MIG or TIG better for stainless steel?

A: TIG offers cleaner welds, but MIG is faster and cheaper.

8. Free Welding Checklist 📝

[🔗 Download Your Free PDF Here]

Includes:

- Pre/post-heat temp guidelines.

- Filler rod selection chart.

- Pressure testing steps.

9. Final Tips 💡

- Practice First: Weld on scrap metal to refine technique.

- Invest in PPE: Fire-resistant jacket, gloves, and auto-darkening helmet.

- Seek Help: Join welding forums (e.g., WeldingWeb) for expert feedback.

🚘 Share this guide to help fellow DIYers silence leaks and hit the road! 🚘

Expand Your Automotive Knowledge 📝

Explore 500+ Free Expert-Curated Guides

🚗 Learn New Skills

From basic maintenance to advanced repairs — clear, actionable tutorials for every skill level.

🌍 Access Anywhere

Mobile-friendly guides with HD visuals. No downloads required.

- Guides & Tutorials

- Car Maintenance 101

- Diagnostics & Troubleshooting

- Seasonal Maintenance

- Budget-Friendly Repairs

- Electrical Systems Guide

- Car Safety & Reliability

- Tools & Product Reviews

- Routine Maintenance

- Car Modifications & Upgrades

- Buying/Selling Guides

- Eco-Friendly Car Care

- Advanced Repairs

- Car Laws & Compliance

- Emergency Repairs

- Future Car Tech