Volvo Fault Codes

Diagnostics

There are several methods to read error codes stored in Volvo control units:

- Self-diagnosis on the instrument cluster: By following a specific button sequence on the panel, fault codes can be displayed on the screen.

- Diagnosis using a scanner and computer: This method requires a special adapter that connects to the vehicle’s connector and a computer or compatible device. By using the appropriate software downloaded from the Internet, error codes can be read and decoded.

- A common method for vehicles from the 90s involves using a self-test plug. This special connector is located in the engine compartment, typically near the left wing (applies to cars manufactured between 1985 and 1995). It consists of a box with an LED, a test start button, a test mode selection cable, and several connectors for connecting the cable. On Volvo 960, 850, and 940 models, the connector is located next to the air filter housing and is covered with a plastic casing. To perform a self-test, insert the cable into the socket and determine the errors by counting the number of LED flashes.

By utilizing these methods, Volvo owners can effectively read and identify error codes stored in their vehicles’ control units.

1985–1995 production machines

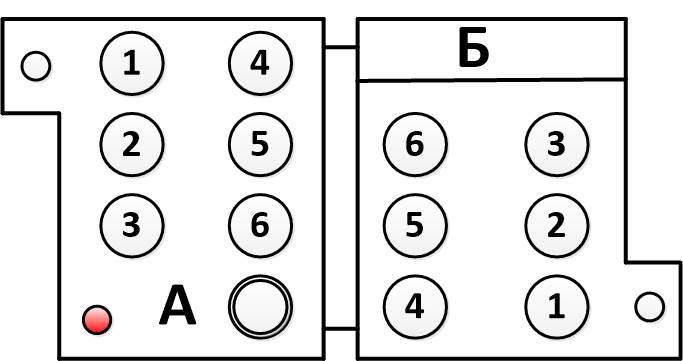

The code of the last diagnostic method has a three-digit format, with each digit being transmitted by the corresponding number of frequent flashes (1 – one, 3 – three, etc.). Between the groups are separated by a pause of three seconds. In the block there are two sections that allow you to receive fault codes of various nodes, each of which has six connectors.

Room / Section A / Section B

1 automatic transmission / Microclimate system (manual and automatic)

2 Fuel supply / Cruise control

3 ABS System / Reserve

4 TCU system on automatic transmission / Airbags and their control unit

5 Ignition system / Seat control

6 The health of the instrument panel / The health of the instrument cluster

To perform diagnostics, you must perform a standard test test:

- Insert the cable into slot 2 of section A.

- Switch on the ignition and briefly press the test start button.

- If there is no error, the LED will discard code 111 (three short flashes at intervals of 3 seconds). If there is an error, it will be reported by other flash combinations.

- Press the test button.

Testing is necessary before repeating the list of errors. The received codes need to be decrypted.

On release machines after 1996

After 1996, a standard OBD-II diagnostic connector with 16 pins was installed on all Volvo cars. This connector is always located in the cabin near the console of the central tunnel or on the dashboard (on trucks). On the C70, V70 or S70 models of production until 1999 it is installed inside the armrest and closed with a removable plastic cover. On the Volvo 850 connector is located in front of the gearshift lever, and at 960 – to the side of the handbrake lever.

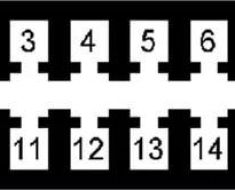

Diagnostics of such machines can be made according to a similar scheme described above, but using a separate diode, which is connected to pin 16 (positive pin) and 4. The device diagram is shown in the pictures below.

When conducting diagnostics and reading errors, it is necessary to take into account that there can be various control units on modern Volvo cars:

VSM – brake control system, including ABS and ESP systems;

SAS – tracking steering angle;

SRS – passive safety management (pillows and belts);

ECM – engine performance control;

AUM – audio system;

CEM – the central electronic control unit;

DIM – instrument cluster;

DDM – electronics in the driver’s door;

CCM – microclimate system;

PDM – electronics in the front right door;

PSM – control of front seats and systems in them;

REM – electronic components of the back of the machine;

SWM – steering;

UEM – additional devices (alarm, sunroof, auto-dimming mirrors, etc.);

TCM – Transmission Control;

DEM – connection of a full drive (Haldex coupling unit).

If there are errors in any of the modules, for example, VSM, an inscription like “VSM DTC SET” will appear on the screen. If there is no error, the text will appear as “VSM Ready”. If a more in-depth analysis of the block is required, the words “SCM Checking” will appear on the combination.

On modern Volvo FH12 or FH13 trucks, errors are displayed on the dashboard as text messages and burning symbols. For a more detailed error analysis on the block of the steering-wheel switches there are several keys with which you can go to the on-board computer menu and read the error code. This code is decoded according to the tables or reported when the truck is handed over for service.

Decoding codes

In total there are about a thousand different fault codes, typical for Volvo cars. Below will be considered the errors that are most often found on the machines.

Р0100 – Р0103 Failure of the air flow sensor itself or its wiring

Р0105 – Р0108 Pressure sensor defective, typical for turbo engines

Р0110 – Р0113 Failure of circuits and air temperature sensor

Р0115 – Р0118 Similarly for engine temperature sensor

Р0120 – Р0123 Throttle flap position sensor is faulty

Р0137 – Р0141 Failure of the lambda probe

Р0142 – Р0147 Damage to the third lambda probe (not available on all machines)

ECM4400 A characteristic problem on the XC90, fuel level sensor failure

Р0451 – Р0453 Breakdown of the pressure sensor in the tank

On machines with the old diagnostic system errors are encountered.

121 Open circuit of air flow sensor

122 Failure of the inlet air temperature sensor

123 and 133 open circuit motor temperature sensor

131 No data on engine speed

132 Network voltage parameters outside the tolerance range

143 Knock sensor defective.

212 Faulty lambda probe and its wiring

214 Crankshaft revolution sensor has problems

221 Problem in lambda probe

243 No signal from throttle sensor (not on all models)

312 Knock sensor defective

344 No signal from the exhaust temperature sensor (turbo only)

332 and 333 Throttle position sensor adjustment required

For trucks, the following sensor errors are common.

PID170 and 171 Failure of temperature sensors in the cabin and on the street

PID117 and 118 Breakdowns of pressure sensors in brake circuits

PID177 Transmission oil temperature sensor failure

On Volvo XC90 with large runs, an error P0027 often occurs, which indicates clogged valves in the phase adjustment system. This problem is corrected by flushing the valve or replacing it with a new one. However, it is not uncommon for an error to occur by chance and no longer bother the owner after deletion.

There are some more common Volvo error codes.

P0171 and P0172 Fuel Mix Enrichment

P0174 and P0175 Excessive impoverishment of the mixture

P0200 Malfunction of the injection injector control unit

Р0201 – Р0212 Failure of nozzles on cylinders

Р0217 Excess of critical temperature of engine

Р0218 Overheating of transmission units

P0243 – P0250 Insufficient pressure in the pressurization system (only for turbo)

Р0231 – Р0233 Malfunctions of the fuel pump

Р0267 – Р0296 Nozzle driver failure (on cylinders)

P0300 General Misfire

Р0301 – Р0312 Cylinder passes

Р0351 – Р0356 Ignition coils are faulty (cylinder)

P0380 Diesel Glow Malfunction

For the old Volvo (until 1995) in the work of the engine errors are most characteristic.

112 Failure of fuel injection control system

113 Failure of one or all nozzles

134 Faulty injection relay.

143 Knock sensor defective.

211 CO regulator (on carburetor engine)

222 Failure of fuel injection relay

223, 232 and 233 Faults in the idle system

For trucks, codes have a double structure.

PID84 Speed Sensor Break

PID91 Failure of the gas pedal position sensor

PID94 Problems with pressure in the fuel supply system

PID97 Water entering the system

PID98 Oil level drop

PID100 Oil Pressure Reduction

PID102 Forced Air Pressure Drop

PID108 Engine block leakage (measured by pressure sensor inside the block)

PID110 Engine Overheating

PID190 Engine Over Speed