Save Thousands of Dollars—Master the Art of Transmission Rebuilds with Pro Tips and Essential Tools!

1. Why Rebuild a Transmission? ⚠️

Rebuilding a transmission is a cost-effective alternative to replacement, saving 1,500–4,000 on labor and parts. Whether restoring a classic car or extending your vehicle’s life, a rebuild offers:

- Customization: Upgrade worn components for better performance.

- Sustainability: Reuse 70–80% of original parts.

- Skill Development: Gain hands-on mechanical expertise.

Key Stat: A professionally rebuilt transmission lasts 100,000–150,000 miles with proper care (ATRA).

2. Essential Tools for the Job 🧰

| Tool | Purpose | Cost |

|---|---|---|

| Transmission Jack | Safely remove/install transmission | 200–500 |

| Torque Wrench | Precise bolt tightening | 50–300 |

| Snap Ring Pliers | Remove internal snap rings | 20–50 |

| Bearing Puller | Extract worn bearings | 40–150 |

| Seal Installer Kit | Replace input/output shaft seals | 30–80 |

| Micrometer | Measure clutch plates and shims | 50–150 |

| Dial Indicator | Check input shaft endplay | 40–100 |

| Parts Cleaning Tank | Degrease components | 80–200 |

Pro Tip: Rent specialty tools (e.g., hydraulic press) from auto stores to save money.

3. Step-by-Step Rebuild Guide 🔧

Step 1: Prep Your Workspace

- Safety First: Wear gloves, goggles, and work in a ventilated area.

- Organize: Label parts with zip-lock bags and take photos during disassembly.

Step 2: Remove the Transmission

- Disconnect the battery and drain fluid.

- Unbolt driveshaft, shift linkage, and torque converter.

- Support the engine with a jack stand.

- Lower the transmission using a transmission jack.

Red Flag: Never let the transmission hang unsupported!

Step 3: Disassemble the Transmission

- External Components: Remove bellhousing, oil pan, and valve body.

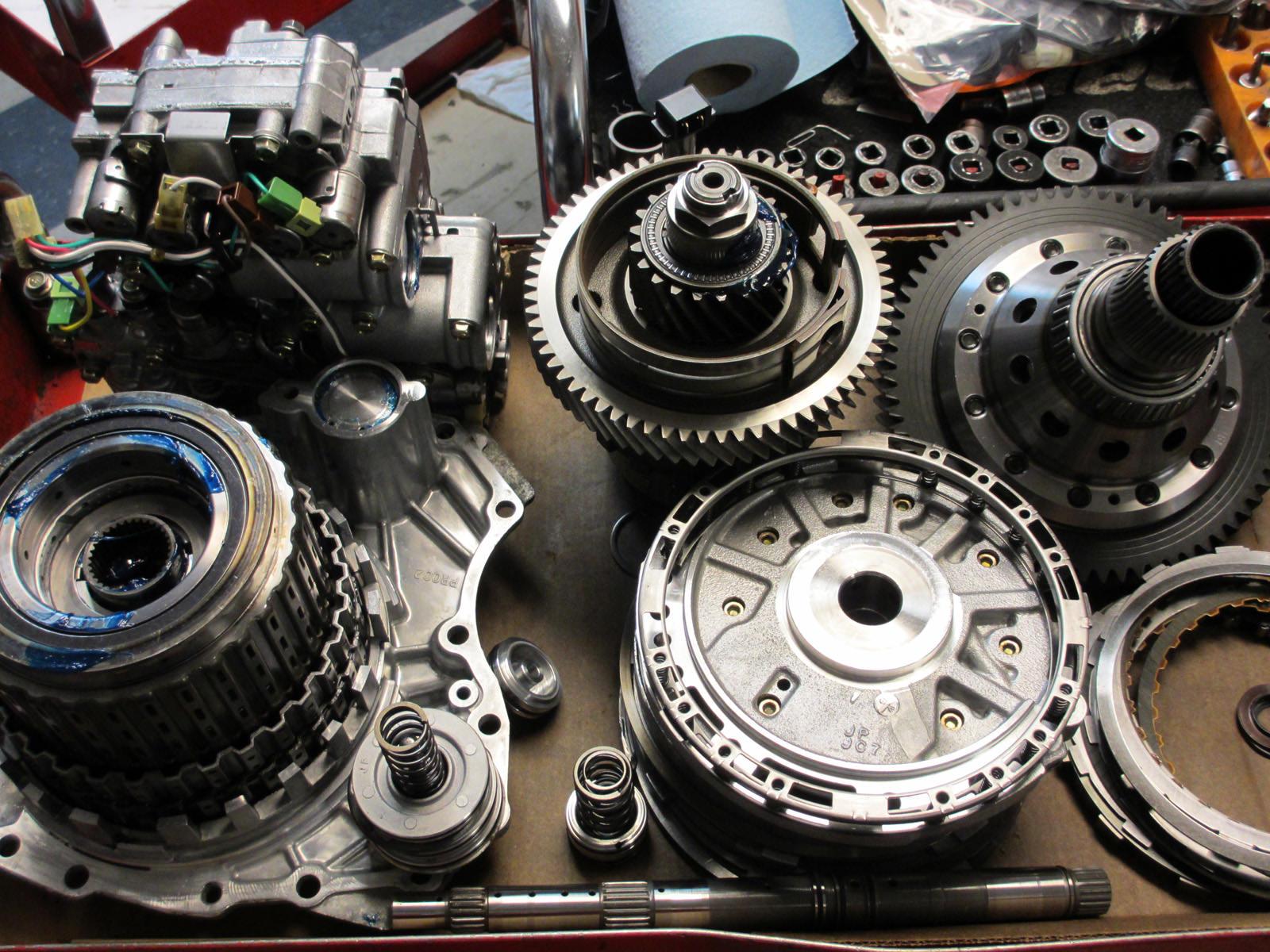

- Internal Components: Extract clutch packs, planetary gears, and drums.

- Inspect: Note worn bearings, burnt clutches, or damaged gears.

Step 4: Clean and Inspect Parts

- Degrease: Soak parts in solvent or use a parts washer.

- Measure: Check clutch plate thickness, gear teeth, and bushings against specs.

- Replace: Worn seals, gaskets, bearings, and damaged gears.

Pro Tip: Replace the torque converter—it’s rarely cost-effective to rebuild.

Step 5: Reassemble the Transmission

- Rebuild valve body with new solenoids (if needed).

- Install new clutch plates, steels, and bands.

- Set endplay using shims (refer to service manual specs).

- Reattach bellhousing and oil pan with fresh RTV sealant.

Step 6: Reinstall and Test

- Mount the transmission with a jack and reconnect all linkages.

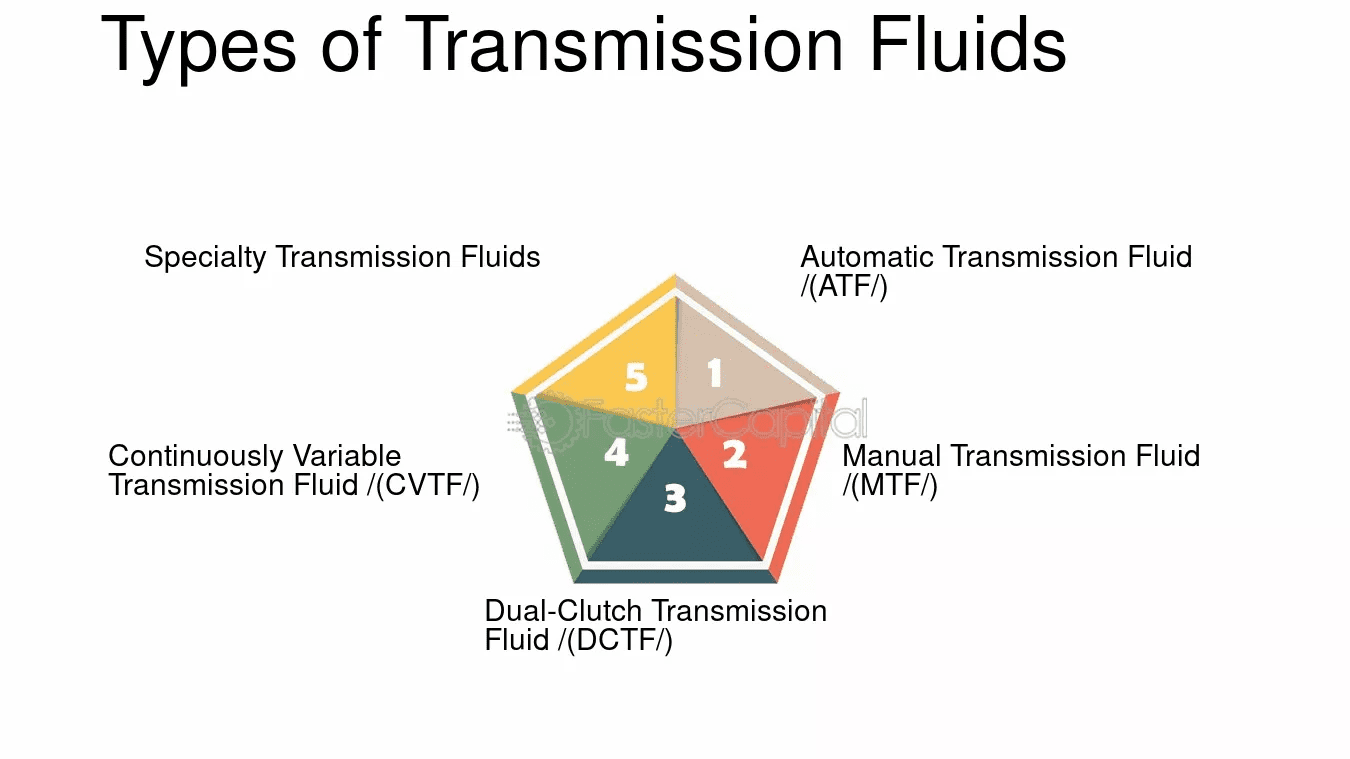

- Refill with 3–5 quarts of manufacturer-recommended fluid.

- Test drive gently, checking for leaks, shifts, and noises.

4. Common Mistakes to Avoid 🚫

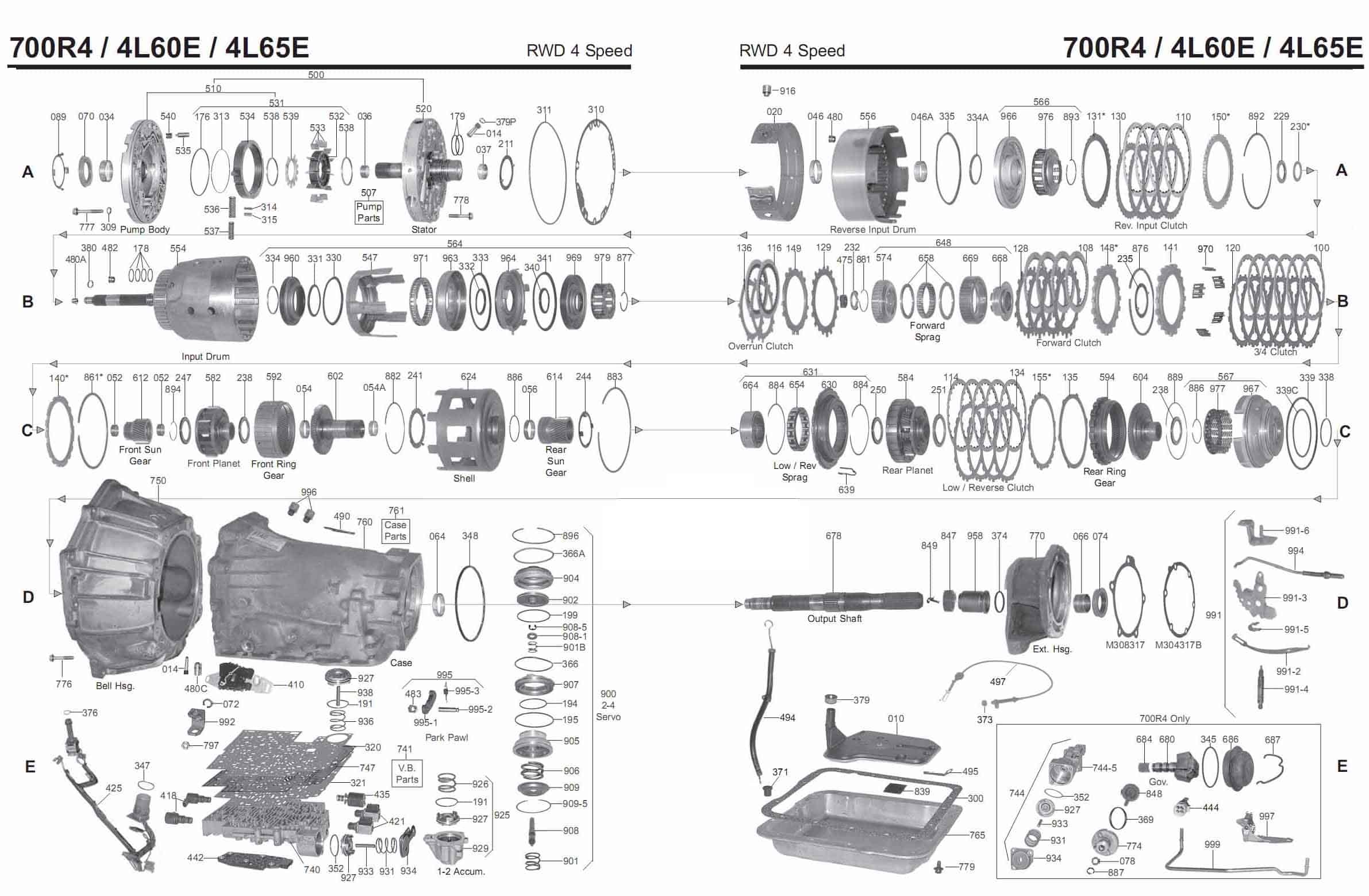

- Skipping the Manual: Each transmission model has unique specs (e.g., Ford 4R70W vs. GM 4L60E).

- Reusing Old Seals: Always install new seals to prevent leaks.

- Overtightening Bolts: Use a torque wrench—valve body bolts often require 8–12 ft-lbs.

- Ignoring Endplay: Incorrect shimming causes premature failure.

Case Study: A misaligned pump led to a $1,200 repeat rebuild on a Honda Accord.

5. Cost Breakdown: DIY vs. Professional 💸

| Expense | DIY Cost | Pro Cost |

|---|---|---|

| Rebuild Kit | 300–800 | 500–1,200 |

| Torque Converter | 150–400 | 300–600 |

| Fluids/Gaskets | 50–100 | 100–200 |

| Labor | $0 | 1,500–3,000 |

| Total | 500–1,300 | 2,400–5,000 |

6. Top 5 Rebuild Kits for 2024 🛒

| Kit | Compatibility | Includes | Price |

|---|---|---|---|

| ATP B-24K | GM 4L60E | Seals, clutches, gaskets, bands | $450 |

| Transgo SK4L60E | GM 4L60E Performance | Alto clutches, shift kit | $600 |

| ATSG Master Kit | Ford 4R100 | Bushings, bearings, seals | $550 |

| Raybestos RYK4T065 | Toyota A340E | Frictions, steels, filter | $380 |

| Sonnax 4L80E Kit | GM 4L80E Heavy Duty | Kolene steels, high-capacity clutches | $700 |

Pro Tip: Opt for kits with OEM-quality components (e.g., Alto, Raybestos).

7. FAQs ❓

Q1: Can a beginner rebuild a transmission?

A: Yes, but expect a steep learning curve. Start with common models (e.g., TH350, 4L60E).

Q2: How long does a rebuild take?

A: 15–25 hours for first-timers; pros finish in 8–12 hours.

Q3: What’s the most challenging part?

A: Valve body reassembly—one misaligned check ball can ruin shifts.

Q4: Should I upgrade components?

A: For towing/performance, install reinforced clutches and a shift kit.

Q5: How do I find transmission specs?

A: Buy a factory service manual (e.g., ATSG Transmission Manual).

8. Free Rebuild Checklist 📝

[🔗 Download Your Free PDF Here]

Includes:

- Step-by-step disassembly guide.

- Torque specs for common transmissions.

- Inspection criteria for worn parts.

9. Final Tips 💡

- Document Everything: Photos prevent “extra parts” syndrome during reassembly.

- Pressure Test: Use an air compressor to check clutch seals before final assembly.

- Join Forums: Sites like Transmission Bench offer expert advice.

🚘 Share this guide to empower fellow gearheads and save them thousands! 🚘

Expand Your Automotive Knowledge 📝

Explore 500+ Free Expert-Curated Guides

🚗 Learn New Skills

From basic maintenance to advanced repairs — clear, actionable tutorials for every skill level.

🌍 Access Anywhere

Mobile-friendly guides with HD visuals. No downloads required.

- Guides & Tutorials

- Car Maintenance 101

- Diagnostics & Troubleshooting

- Seasonal Maintenance

- Budget-Friendly Repairs

- Electrical Systems Guide

- Car Safety & Reliability

- Tools & Product Reviews

- Routine Maintenance

- Car Modifications & Upgrades

- Buying/Selling Guides

- Eco-Friendly Car Care

- Advanced Repairs

- Car Laws & Compliance

- Emergency Repairs

- Future Car Tech