Table of Contents

Don’t Let a Bumpy Ride Turn into a Costly Disaster—Learn to Diagnose and Fix Suspension Issues Like a Pro!

1. Why Suspension Health Matters ⚠️

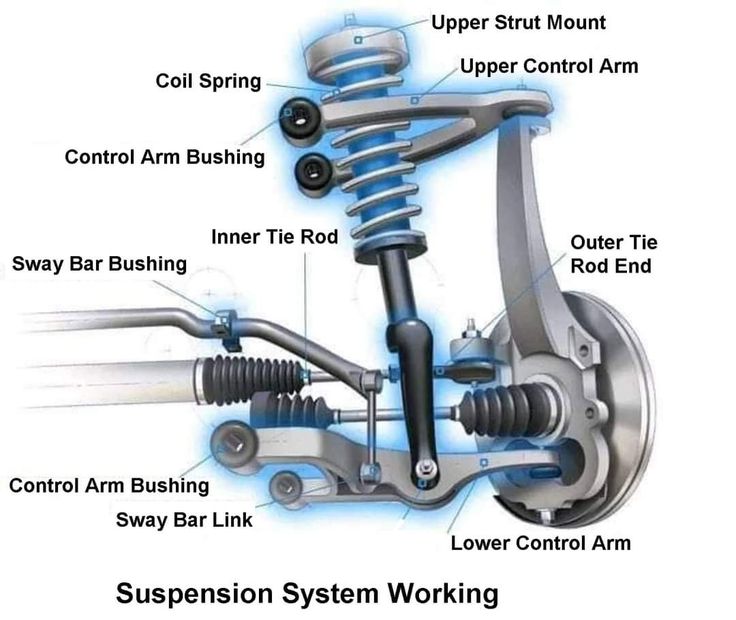

Your car’s suspension is its backbone, absorbing shocks and keeping you stable. Ignoring worn parts leads to:

- Safety risks: Poor handling increases rollover and collision risks.

- Premature tire wear: Misalignment wears tires 30% faster.

- Costly repairs: A failed strut can damage axles, CV joints, or even the frame.

Key Stat: 20% of vehicles on the road have worn suspension components (NHTSA).

2. 6 Signs Your Suspension Is Failing 🚨

- Bouncing or Swerving: The car dips forward after braking or sways on turns.

- Knocking Noises: Clunks over bumps (worn bushings or ball joints).

- Uneven Tire Tread: Bald patches on inner/outer edges.

- Fluid Leaks: Oily residue on shocks/struts.

- Pulling to One Side: Misalignment from worn control arms.

- Visible Rust/Cracks: Corrosion on springs or linkages.

Pro Tip: Test the “bounce test”—press down on each corner. If it bounces >2x, shocks are weak.

3. Tools You’ll Need for Inspection 🧰

- Jack and jack stands

- Flashlight

- Pry bar

- Torque wrench

- Tire tread gauge

- Cost: Basic toolkit (50–150) vs. professional scan tool ($200+).

4. Step-by-Step Suspension Inspection Guide 🔍

Step 1: Visual Check

- Look for leaks: Shocks/struts should be dry.

- Inspect bushings: Cracks or gaps mean replacement.

- Check springs: Rust or sagging? Replace ASAP!

Step 2: Test for Play

- Ball joints: Lift the wheel and wiggle it (9 & 3 o’clock). Movement = worn joint.

- Tie rods: Shake the wheel at 12 & 6 o’clock. Play indicates tie rod wear.

- Control arms: Use a pry bar to check bushing flexibility.

Warning: Never skip wheel chocks—safety first! ⚠️

Step 3: Measure Tire Wear

Use a tread gauge. Uneven wear? Suspect alignment or worn strut mounts.

Pro Tip: Mark bolts with paint before disassembly for easier reassembly.

5. How to Replace Common Suspension Parts 🛠️

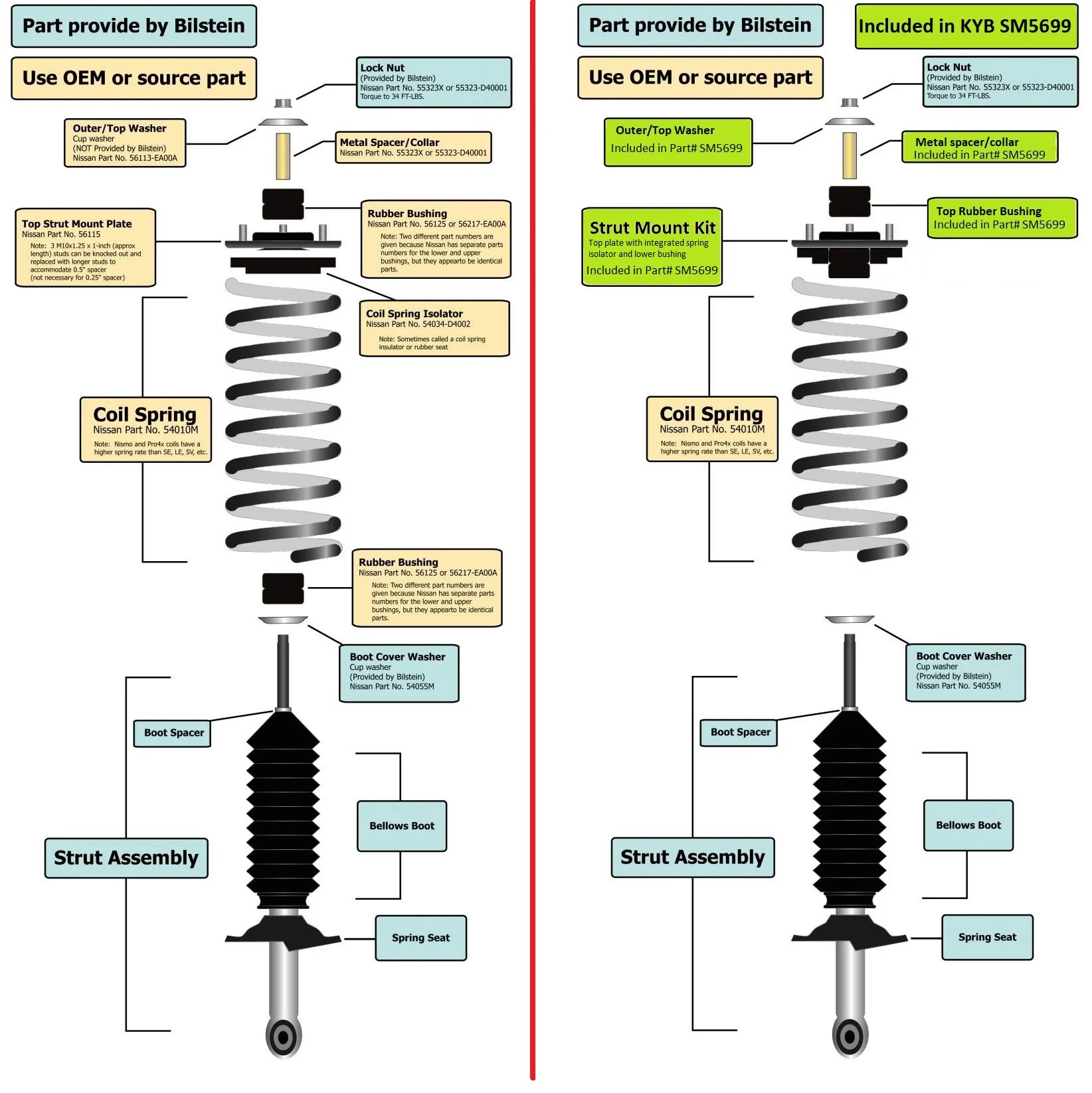

① Shocks/Struts

- Lift the car and remove the wheel.

- Unbolt the shock/strut (top mount and lower linkage).

- Use a spring compressor to swap springs onto the new strut.

- Torque bolts to spec (e.g., 50–70 ft-lbs for most cars).

Cost: 80–200 per strut (DIY) vs. $500+ (mechanic).

② Control Arms

- Remove the ball joint nut and separate it from the knuckle.

- Unbolt the control arm from the frame.

- Install the new arm and torque bolts.

Pro Tip: Replace bushings and ball joints together to save labor.

③ Sway Bar Links

- Unbolt the link from the sway bar and control arm.

- Install the new link—ensure it’s snug but not overtightened.

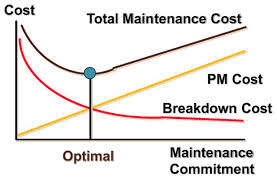

6. Consequences of Delaying Repairs 💸

- Alignment costs: 100–300 per session.

- Tire replacement: 400–800 for a set.

- Accident risks: NHTSA links 12% of crashes to suspension failure.

7. Top 5 Suspension Repair Tools 🛒

| Tool | Price | Best For |

|---|---|---|

| OTC Strut Spring Compressor | $90 | Safe spring removal |

| Tekton Torque Wrench | $60 | Precise bolt tightening |

| Lisle Ball Joint Press | $45 | Replacing joints |

| Powerbuilt Hub Grappler | $30 | Separating stuck ball joints |

| OEM Control Arm Kit | 120–300 | Full arm replacement |

8. FAQs ❓

Q1: How often should I inspect my suspension?

A: Every 12,000 miles or if you notice handling changes.

Q2: Can I drive with a broken suspension spring?

A: No! It can puncture tires or cause sudden loss of control.

Q3: Why does my car vibrate at high speeds?

A: Worn bushings, unbalanced tires, or bent control arms.

Q4: How long do suspension parts last?

A: Shocks/struts: 50k–100k miles; bushings: 80k miles.

Q5: Do I need an alignment after replacing parts?

A: Yes—always align after suspension work.

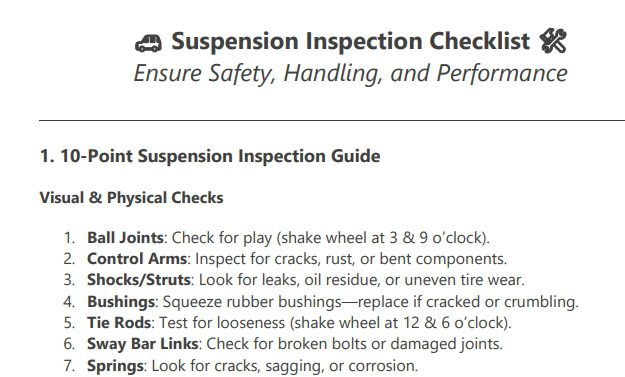

9. Free Suspension Inspection Checklist 📝

[🔗 Download Your Free PDF Here]

Includes:

- 10-point inspection guide.

- Torque specs for common models.

- Emergency repair tips.

Final Tips 💡

- Upgrade for heavy loads: Install heavy-duty shocks if you tow.

- Avoid potholes: They bend control arms and crack springs.

- Lubricate bushings: Use silicone spray to slow dry-rot.

🚙 Share this guide to help friends avoid suspension disasters! 🚙

Expand Your Automotive Knowledge 📝

Explore 500+ Free Expert-Curated Guides

🚗 Learn New Skills

From basic maintenance to advanced repairs — clear, actionable tutorials for every skill level.

🌍 Access Anywhere

Mobile-friendly guides with HD visuals. No downloads required.

- Guides & Tutorials

- Car Maintenance 101

- Diagnostics & Troubleshooting

- Seasonal Maintenance

- Budget-Friendly Repairs

- Electrical Systems Guide

- Car Safety & Reliability

- Tools & Product Reviews

- Routine Maintenance

- Car Modifications & Upgrades

- Buying/Selling Guides

- Eco-Friendly Car Care

- Advanced Repairs

- Car Laws & Compliance

- Emergency Repairs

- Future Car Tech