Table of Contents

Stop Brake Pulsation—Learn DIY Fixes, Save Money, and Restore Smooth Stopping Power!

1. Why Rotors Warp and How to Spot It ⚠️

Brake rotors warp due to uneven heat distribution, often caused by:

- Hard braking: Repeated stops from high speeds.

- Improper torque: Over-tightened or uneven lug nuts.

- Rust/corrosion: Creates uneven rotor surfaces.

- Poor-quality rotors: Thin or cheap materials degrade faster.

Symptoms of a Warped Rotor:

- Steering wheel vibration during braking.

- Pulsating brake pedal.

- Squealing or grinding noises.

Key Stat: Warped rotors reduce braking efficiency by 20–30% and accelerate pad wear (NHTSA).

2. Machining vs. Replacement: Quick Comparison 📊

| Factor | Machining | Replacement |

|---|---|---|

| Cost | 20–50 (DIY) / 25–75 (pro) | 50–300 per rotor (parts) |

| Time | 2–3 hours | 1–2 hours |

| Longevity | 10,000–20,000 miles | 30,000–70,000 miles |

| Tools Needed | Brake lathe, micrometer, drill | Jack, lug wrench, torque wrench |

| Best For | Minor warping, thick rotors | Severe warping, thin/rusted rotors |

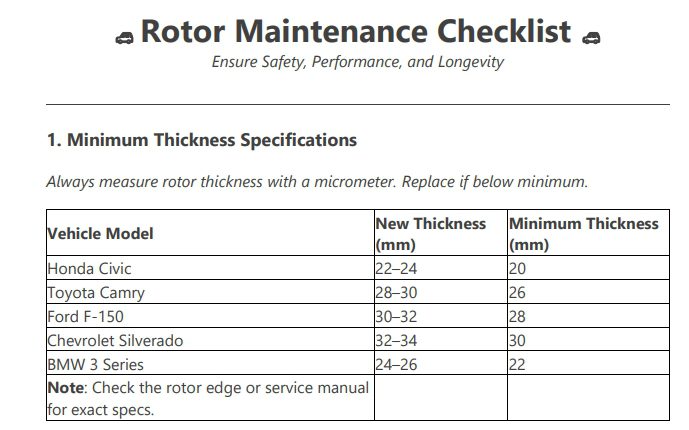

Pro Tip: Always measure rotor thickness before machining. If below the minimum discard thickness (stamped on the rotor), replace it!

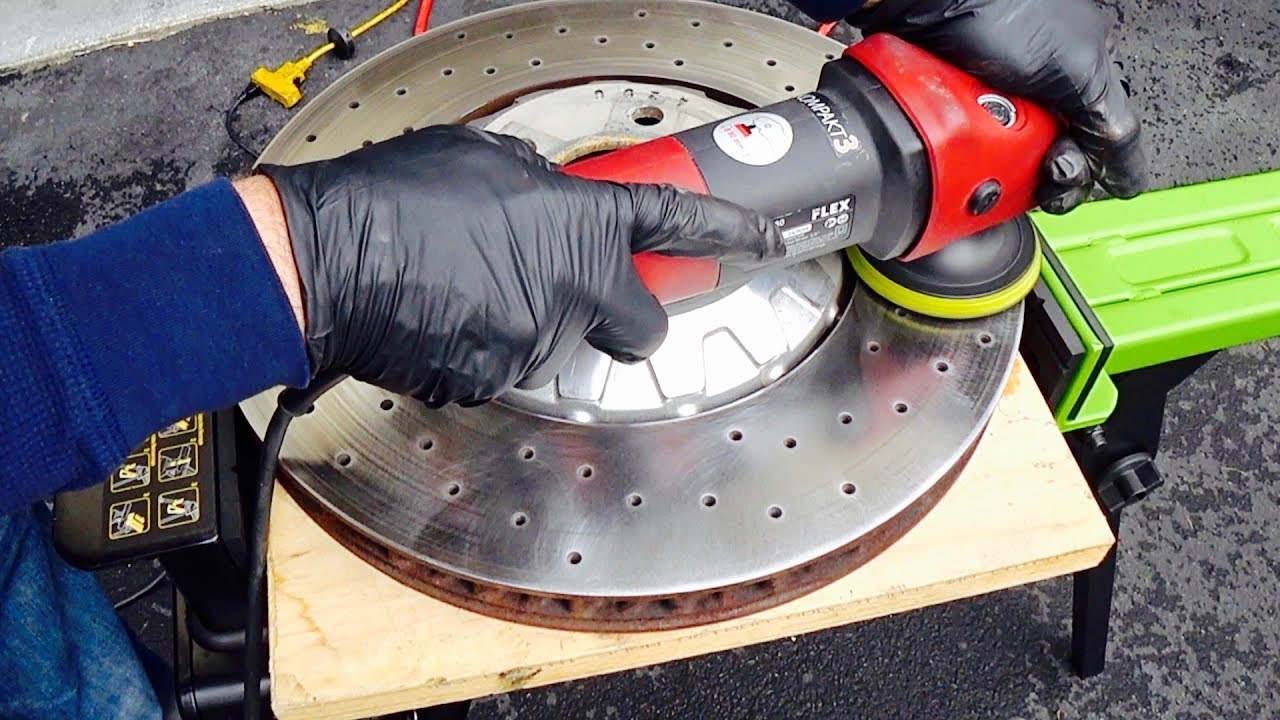

3. How to Machine Rotors at Home 🛠️

Tools Needed:

- Brake lathe (e.g., Fenix LD-20 On-Car Lathe: 300–600).

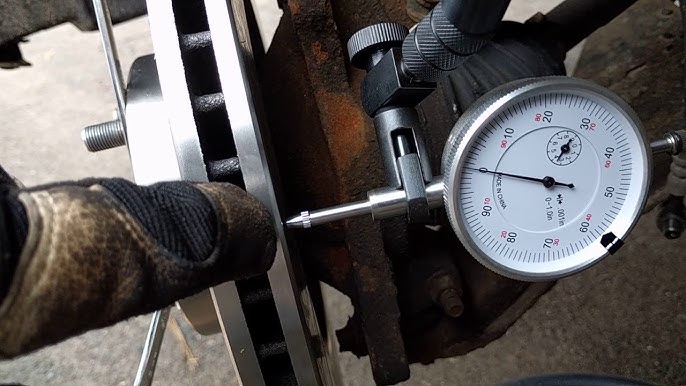

- Dial indicator or micrometer.

- Drill or rotor resurfacing tool (e.g., DIY Brake Rotor Resurfacer Kit: $150).

Steps:

- Remove the rotor: Jack up the car, remove the wheel, and unbolt the rotor.

- Measure thickness: Ensure it’s above the manufacturer’s minimum spec.

- Mount the rotor: Secure it on the lathe or drill-powered resurfacer.

- Resurface: Make light, even passes until smooth (remove ≤0.005” per side).

- Clean and reinstall: Degrease with brake cleaner and bed in new pads.

Pros:

- Saves money if rotors are thick enough.

- Eco-friendly (reduces waste).

Cons:

- Short-term fix; warping may recur.

- Not possible for thin/rusted rotors.

4. How to Replace Rotors at Home 🛠️

Tools Needed:

- Jack and jack stands.

- Lug wrench and torque wrench.

- Anti-seize lubricant.

- New rotors (OEM or performance brands like Brembo or Power Stop).

Steps:

- Remove the old rotor:

- Lift the car, remove the wheel, and unbolt the caliper (hang it with a wire).

- Remove the caliper bracket and slide off the rotor.

- Prep the hub: Scrub off rust with a wire brush; apply anti-seize.

- Install the new rotor: Align it on the hub and reassemble components.

- Torque bolts: Lug nuts to spec (75–100 ft-lbs for most cars).

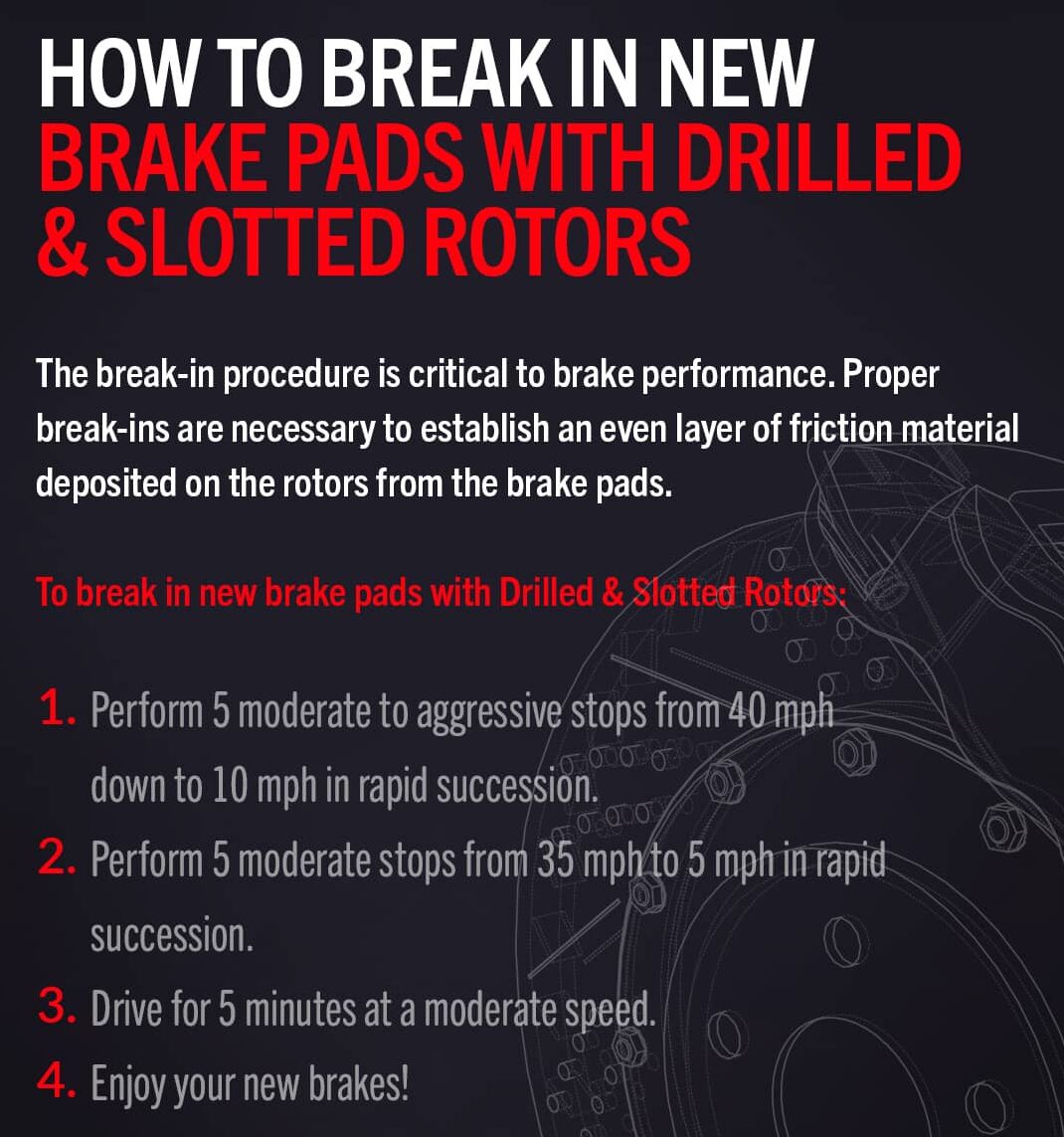

- Bed-in pads: Follow the manufacturer’s heat-cycling process.

Pros:

- Restores 100% braking performance.

- Longer lifespan than machined rotors.

Cons:

- Higher upfront cost.

- Requires proper disposal of old rotors.

5. When to Machine vs. Replace 🛑

Machine If:

- Rotor thickness is above the minimum spec.

- Warping is minor (e.g., slight vibration).

- You’re on a tight budget.

Replace If:

- Rotors are cracked, deeply scored, or rusted.

- Thickness is near or below discard specs.

- You’re upgrading to slotted/drilled rotors for performance.

Case Study: A 2015 Honda Civic saved $200 by machining rotors, but warping returned in 8,000 miles.

6. Common Mistakes to Avoid 🚫

- Reusing old pads: Glazed pads can re-warp rotors.

- Skipping bed-in: New pads/rotors need proper heat cycling.

- Ignoring hub cleaning: Rust causes uneven mounting.

- Overtightening lug nuts: Use a torque wrench!

7. Cost Breakdown 💸

| Item | Machining | Replacement |

|---|---|---|

| Rotor Cost | $0 | 50–300 each |

| Tools/Equipment | 150–600 | 50–200 (jack, etc.) |

| Labor (Pro) | 25–75 per rotor | 100–300 total |

| Total (DIY) | 20–600 | 100–500 |

8. FAQs ❓

Q1: Can I machine rotors without a lathe?

A: Yes—use a drill with a resurfacing kit, but results vary.

Q2: Do I need new pads when replacing rotors?

A: Always replace pads with new rotors for optimal performance.

Q3: How long do machined rotors last?

A: 10K–20K miles if driven gently; less with aggressive braking.

Q4: Can I mix old and new rotors?

A: Never! Replace rotors in axle pairs (front/rear).

Q5: Why does my steering still shake after machining?

A: Hub runout, unbalanced tires, or suspension issues may be the culprit.

9. Free Rotor Maintenance Checklist 📝

[🔗 Download Your Free PDF Here]

Includes:

- Minimum thickness specs for common vehicles.

- Bed-in procedures for new rotors.

- Torque specs by car model.

10. Final Tips 💡

- Check runout: Use a dial indicator to ensure the rotor sits evenly on the hub.

- Upgrade wisely: Slotted rotors reduce glaze but wear pads faster.

- Go OEM for reliability: Cheap rotors warp easier.

🚘 Share this guide to help fellow drivers stop safely and save cash! 🚘

Expand Your Automotive Knowledge 📝

Explore 500+ Free Expert-Curated Guides

🚗 Learn New Skills

From basic maintenance to advanced repairs — clear, actionable tutorials for every skill level.

🌍 Access Anywhere

Mobile-friendly guides with HD visuals. No downloads required.

- Guides & Tutorials

- Car Maintenance 101

- Diagnostics & Troubleshooting

- Seasonal Maintenance

- Budget-Friendly Repairs

- Electrical Systems Guide

- Car Safety & Reliability

- Tools & Product Reviews

- Routine Maintenance

- Car Modifications & Upgrades

- Buying/Selling Guides

- Eco-Friendly Car Care

- Advanced Repairs

- Car Laws & Compliance

- Emergency Repairs

- Future Car Tech