Build Your Own Cold Air Intake: A DIY Guide to Boost Performance

Table of Contents

⚠️ Disclaimer:

Modifying your vehicle’s intake system can affect engine performance and warranties. Work at your own risk. Always follow safety guidelines.

Why Build a Custom Cold Air Intake?

- Increased Horsepower: Cooler air = denser fuel mixture = more power.

- Improved Throttle Response: Smoother airflow enhances acceleration.

- Cost Savings: Build for 40–40–60 vs. $200+ for pre-made kits.

- Customization: Tailor the design to your engine bay and driving needs.

Tools & Materials

| Item | Details |

|---|---|

| Mandrel-Bent Steel Tubing | 180-degree U-bend, 2.5″–3″ diameter (match engine size). |

| K&N Cone Filter | 6″ length, 3″ opening (e.g., RU-3590). |

| Rubber PVC Clamps | 2″ size (4x), high-temp rated. |

| High-Temp Ceramic Paint | Dupli-Color or Plasti-Coat (heat-resistant, engine-safe). |

| Crankcase Vent Kit | 3/8″ rubber grommet, plastic/vinyl tubing. |

| Basic Tools | Hacksaw, drill, sandpaper, screwdriver, silicone grease. |

Step 1: Prep the Piping

- Cut the Tubing:

- Use the stock intake as a template.

- Measure and mark bends using a hacksaw or cutting wheel.

- Smooth edges with sandpaper to prevent airflow turbulence.

- Test Fit:

- Dry-fit sections from the throttle body to the bumper opening.

- Adjust angles for optimal clearance (avoid sharp bends).

Step 2: Install the Intake

- Remove Stock Components:

- Detach the airbox, resonator, and bumper (if needed).

- Assemble the System:

- Lubricate rubber clamps with silicone grease for easier fitting.

- Connect sections in this order:

- Throttle body → Upper pipe → Middle pipe → Lower pipe.

- Secure with clamps (no gaps allowed!).

- Hydrolock Prevention:

- For rainy climates, mount the filter higher (shorten the lower pipe).

Step 3: Add Crankcase Vent

- Drill a 3/8″ Hole:

- Locate near the valve cover vent (reference stock intake).

- Install Grommet & Tubing:

- Insert the plastic tube (1″ inside, 2″ outside).

- Connect vinyl hose to the valve cover.

Pro Tip: Avoid kinks—ensure smooth airflow.

Step 4: Paint & Protect

- Clean Thoroughly:

- Degrease pipes, then wipe with isopropyl alcohol.

- Spray Paint:

- Apply 3 light coats inside the pipes first (prevents rust, smooths airflow).

- Paint the exterior with 4 coats for heat resistance.

- Dry & Inspect:

- Cure overnight. Remove debris with a cloth dragged through the pipes.

Step 5: Final Assembly

- Reattach Components:

- Bolt the filter to the lower pipe from under the bumper.

- Reconnect Sensors:

- OBD-II Cars (1996+): Drill a second hole for the intake air temp sensor.

Pro Tips for Success

- Use Mandrel Bends: Maintains pipe diameter for unrestricted airflow.

- Avoid Oversized Pipes: 3″ suits Type R/H-series engines; 2.5″ for smaller motors.

- Check for Leaks: Spray soapy water on joints—bubbles indicate gaps.

Troubleshooting FAQ

Q: Will this void my warranty?

A: Potentially. Check your manufacturer’s guidelines before modifying.

Q: My engine runs lean after install. Why?

A: Incorrect pipe sizing or air leaks. Use a OBD-II scanner to monitor AFR.

Q: Can I reuse the stock MAF sensor?

A: Yes—ensure the pipe diameter matches the sensor housing.

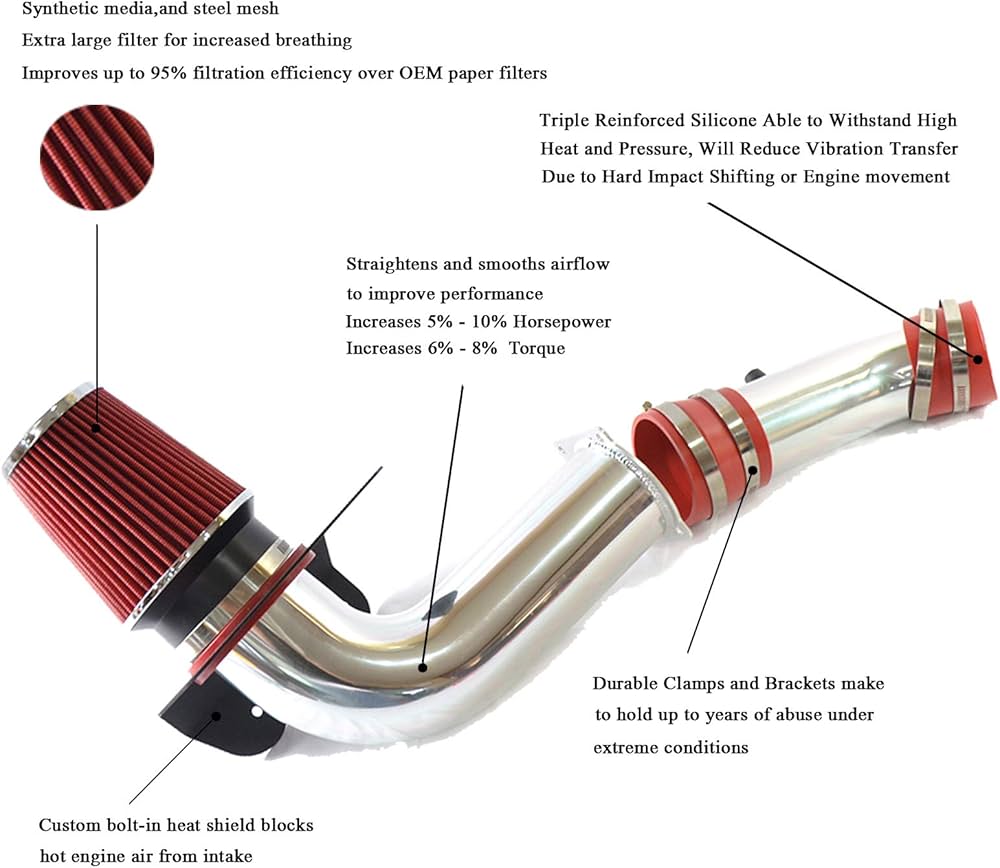

When to Buy a Pre-Made Kit

- Lack tools/time for fabrication.

- Own a turbocharged/intercooled engine (requires precise tuning).

Conclusion

A custom cold air intake unlocks your engine’s hidden potential. Share your build online, and tag us to showcase your craftsmanship!

Expand Your Automotive Knowledge 📝

Explore 500+ Free Expert-Curated Guides

🚗 Learn New Skills

From basic maintenance to advanced repairs — clear, actionable tutorials for every skill level.

🌍 Access Anywhere

Mobile-friendly guides with HD visuals. No downloads required.

- Guides & Tutorials

- Car Maintenance 101

- Diagnostics & Troubleshooting

- Seasonal Maintenance

- Budget-Friendly Repairs

- Electrical Systems Guide

- Car Safety & Reliability

- Tools & Product Reviews

- Routine Maintenance

- Car Modifications & Upgrades

- Buying/Selling Guides

- Eco-Friendly Car Care

- Advanced Repairs

- Car Laws & Compliance

- Emergency Repairs

- Future Car Tech